Dirt Simple Implementation

Our AHS is as simple as driving from A to B. Pronto’s software learns a haul route from a mining operator driving a vehicle manually on the desired route, just one time. Operators then dispatch trucks to saved routes from their smartphones via Pronto’s easy-to-operate mobile app.

This straightforward implementation reduces the time and capital needed to introduce autonomy into your fleet. It requires little, if any, infrastructure modifications.

Superior Technology Systems for Advanced Safety

To meet the rigid safety requirements of mine operators, Pronto’s turnkey software+hardware system enables protection that includes:

- Precise situational awareness via computer vision, and GNSS

- A rugged camera and GPS-based hardware stack that is lighter, faster, and more affordable than radar and lidar-based systems

- Advanced object detection through the latest machine learning capabilities to reduce false positives, decreasing downtime and shutdowns

- A retrofit drive-by-wire kit to actuate any vehicle with precision

- Easily programmable software to add site-specific operational safeguards and rules of the road

- All-stop buttons provided in all manually operated equipment that interact with our AHS

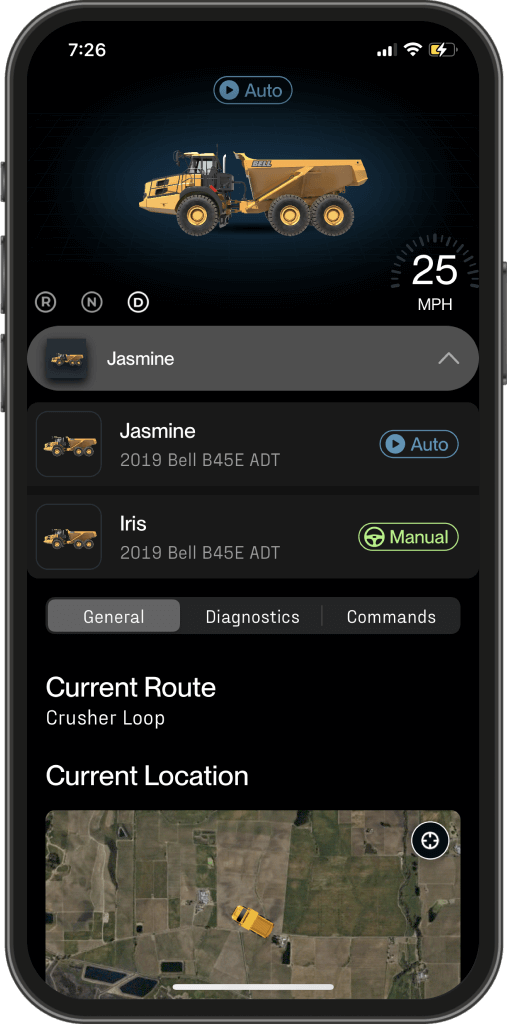

Supervise and Dispatch from the Palm of Your Hand

Pronto’s convenient smartphone app does away with the need for a complex, expensive AHS control room while still providing:

- Access control for authorized personnel

- Notification of AHS activity

- Fleet performance and location monitoring

- Individual truck metrics, including fuel, payload, and utilization

- Source and destination selection of your material movements

How we stack up

| Safety features | Other AHS | Pronto AHS |

|---|---|---|

| Designed to respond to unpredictable events in high-traffic environments | ||

| AI-powered collision threat detection | ||

| Sensors used to ensure safety: | ||

| Camera | ||

| Radar | ||

| GPS | ||

| Lidar (brittle and limited) | ||

| Collision threat detection and response in absence of GPS and/or network | ||

| Detection of collision threats without radar signatures (pedestrians, animals, certain types of rocks) | ||

| Redundant neural networks | ||

| “Rover” systems on other equipment for safe operation of manned vehicles alongside autonomous units | ||

| Site optimization | ||

| System health checks | ||

| Functional in snow, rain and other harsh conditions | ||

| Autonomous operating zones | ||

| Minimal hardware points of failure |

Activating Wireless Connectivity for Autonomous Solutions

Wireless connectivity is a requirement for every AHS deployment. To address this need more affordably, we launched a subsidiary – Pollen Mobile. Pollen uses open-source mobile technologies that allow us to deploy reliable, secure wireless LTE networks to mine sites at a fraction of the cost.